Good Manufacturing Practice

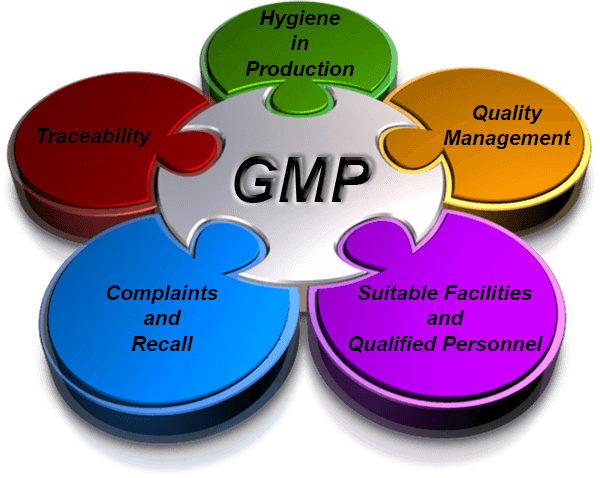

Drug quality affects everyone involved in Clinical Research in one way or another. Undoubtedly, consumers expect that the pharmaceutical medicaments which they take will meet all necessary quality standards and requirements so that the use of medicines is not only effective but safe too. However, not everyone is well aware and well informed in terms of what Good Manufacturing Practice is and what its enforced regulations actually do. Accordingly, GMP serves to make sure that proper design, monitoring as well as control of different manufacturing processes is being carried out.

What is more, its regulations also ensure that absolute quality, strength, efficacy and purity of products is being appropriately obtained by manufacturers. Once, and only when they put into practice such system of controls and quality standards, companies in the Pharmaceutical industry will be able to adequately escape undesirable failures, errors and even contaminations. In addition to this, something that defines the usefulness and the practicality of Good Manufacturing Practices is the sensible flexibility of its demands. For instance, thanks to this versatility firms have the opportunity to conduct more modern approaches by taking advantage of advanced and updated technologies.

Changes and their necessity

Yet, there are some recent changes in the GMP which have been made so that the principles of Pharmaceutical Quality System could be integrated. Some of these changes are mostly directed towards the employees. For instance, the hired personnel are required to have the necessary qualities, skills, and, last but not least, sufficient experience as well as expertise. Furthermore, in order to manage the quality management system and to gradually enhance its usefulness, senior management has the responsibility to ensure that appropriate human, financial, material, facility and equipment recourses are provided. Additionally, senior management should establish a quality policy which thoroughly indicates the general intentions and direction of the company in terms of quality. There should be an organization chart which depicts the relationship between the heads of Production, Quality Control and Head of Quality Assurance or Quality Unit and the position of the Qualified Person(s). Finally, people are expected to have certain duties assigned to them, recorded in written job descriptions.

General

It is of a great significance that a Key Management Personnel is being appointed with key responsibilities. Thus, the key personnel include a head of the Production Department who has the role to guarantee that products are developed and preservedin accordance with the appropriate documentation so that the required quality can be obtained. The head of the Production Department also ensures the strict implementation of production operations. Finally, he/she makes sure that the training of his/her department personnel is successfullyconducted and completed. Head of Quality Control is also part of the key personnel. His/Her initial responsibilities are: approving or rejecting starting materials, packaging materials, intermediate, bulk and finished products; approving specifications, sampling instructions, test methods and other Quality Control procedures etc.

Training

As mentioned before, training is important so all the personnel with duties that may affect the quality of the product should go through a training provided by the manufacturer. Nevertheless, the basic training regarding the quality management system and Good Manufacturing Practice might not be enough so the most recently hired people should also receive more extensive training appropriate to their duties.

Some tips regarding training

Specific training should be given to personnel working in clean areas or areas where active, toxic, infectious or sensitising materials are kept. Another important thing is that untrained personnel or visitors should not be taken into the production and quality control areas. Lastly, thetraining sessions should include discussions about the pharmaceutical quality system and the ways in which it can be improved.

Personnel Hygiene

When it comes to the medical products and their quality, hygiene is something crucial. That is why hygiene programmes should be established and allocated to the requirementsof the factory. All employees should receive medical examination upon recruitment. Moreover, everyone who enters the manufacturing areas should be equipped withprotective garments appropriate to the specific operations which are to be carried out.

Consultants

All consultants are supposed to have received appropriate education and sufficient training and should have gained enough experience so that they can provide with reliable information around their subject of expertise.

Conclusion

To sum up, a lot of pharmaceutical manufacturers have already started using and benefiting from comprehensive, updated quality systems and approaches to guarantee the best possible drugs without endangering the consumer or public. The high quality of the products depends on the Good Manufacturing Practice and its principles which offer guidance for manufacturing, testing, and quality of a medical productso that it can be confirmed as safe and appropriate for human consumption.